Aviation Spark Plugs

World’s Best Aviation Spark Plugs!

Tempest® Aviation Spark Plugs

The most automated manufacturing processes and the most innovative spark plug in the aviation industry.

The most automated manufacturing processes and the most innovative spark plug in the aviation industry.

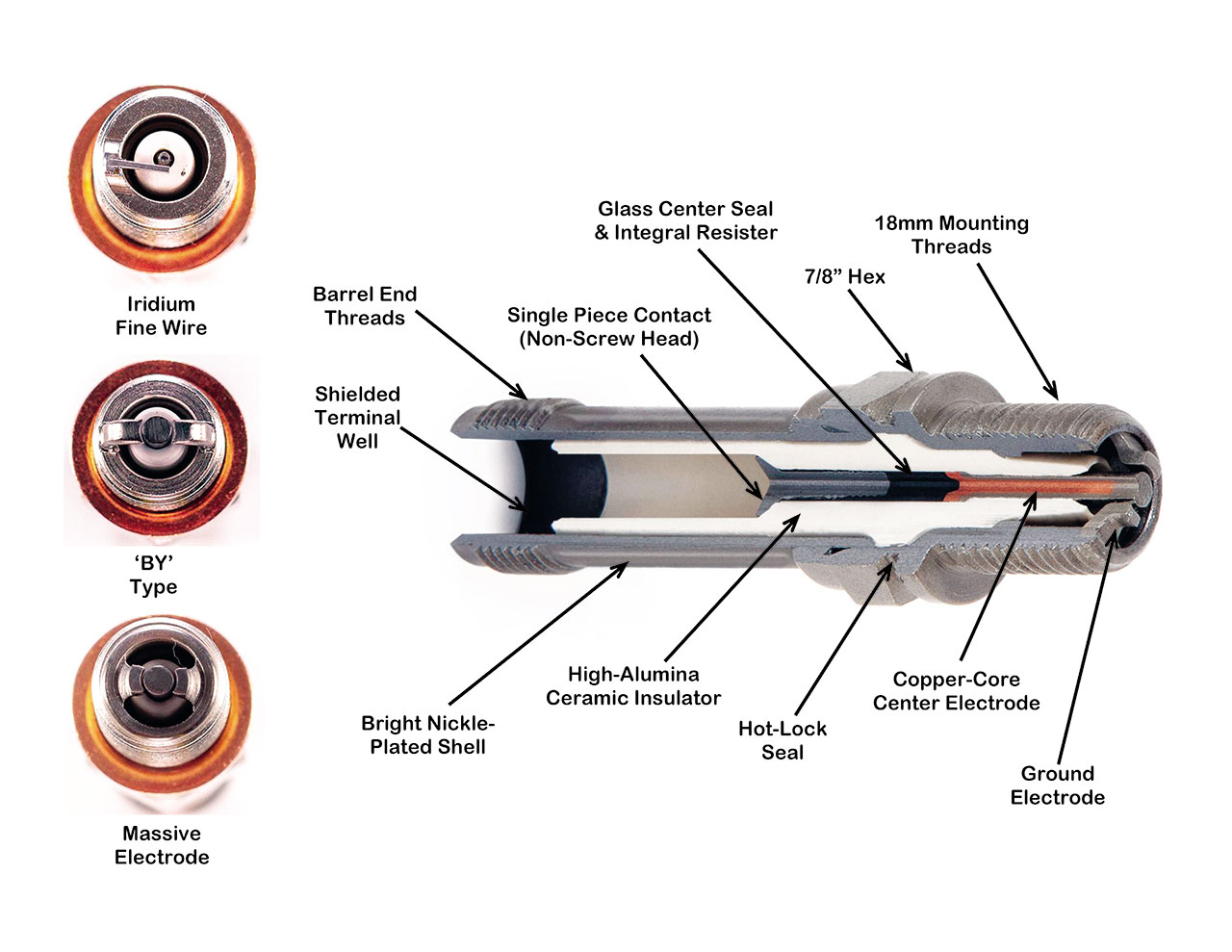

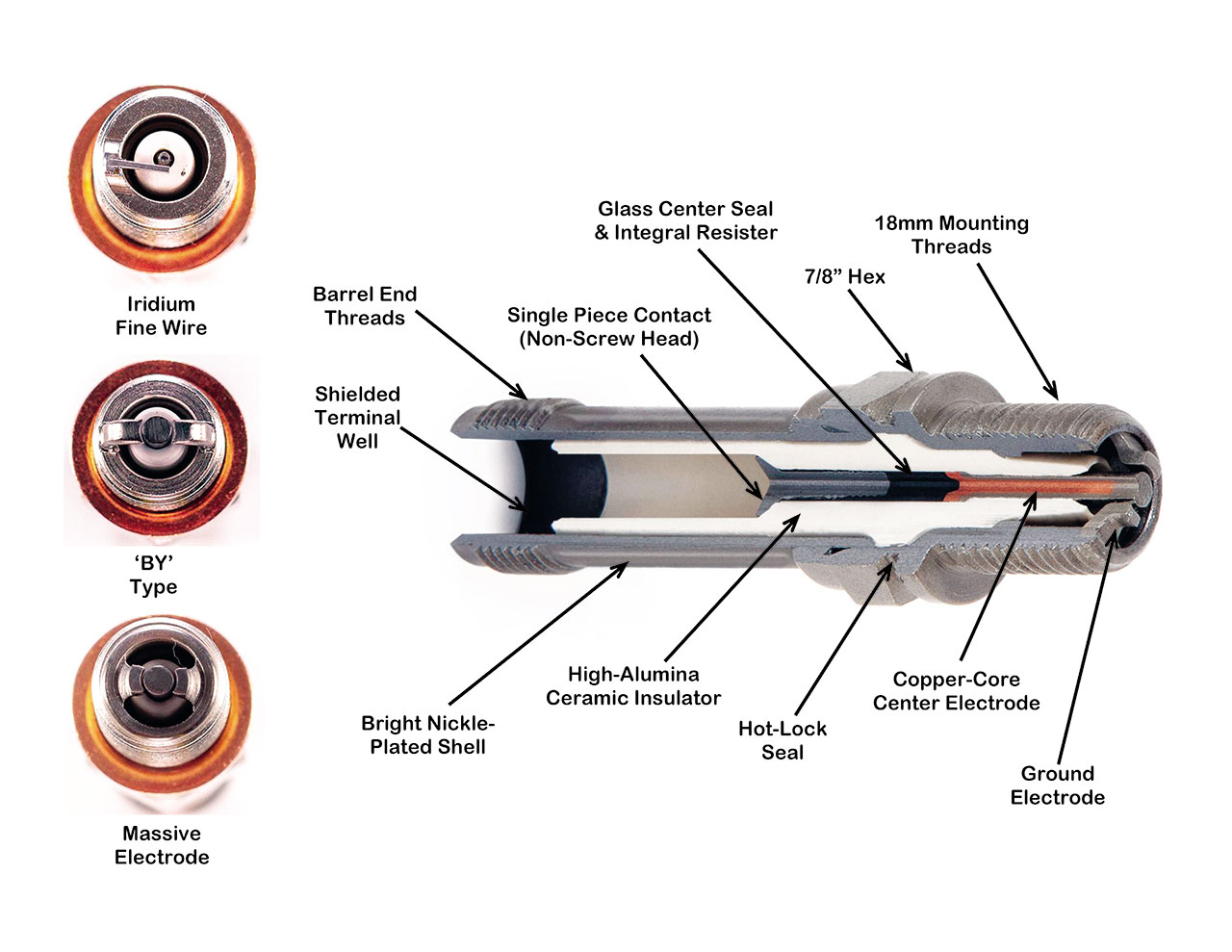

High Conductivity Copper Core Center Electrode

Copper, co-extruded inside a nickel alloy sleeve ensures outstanding heat and electrical conductivity while the nickel sleeve offers high resistance to corrosive combustion gases.

Proprietary Glass Center Seal

21st century ‘fired in’ resistor replaces the multipart screw, spring, and carbon pile stack up used in competitive plugs and known to suffer from resistance value instability that can cause misfires, wasted fuel, and engine roughness.

High Alumina Ceramic Insulator

High mechanical strength, superior dielectric properties, and proprietary protective glaze, provides high performance to conquer severe operational conditions. “Clean Collar” massive electrode “V” tip focuses heat to reduce fouling and enhance heat range control.

Nickel Finish

Environmentally preferable electrolytic nickel provides outstanding durable finish, superior corrosion protection, and extreme wear resistance.

Nickel Ground Electrodes

Aviation grade nickel electrode design focuses on minimizing sparking voltage requirements while maintaining specification gaps to ensure large, stable ‘flame kernels’ for on-time ignition and complete combustion

Vacuum Infused Center Electrode

The proprietary vacuum infusion process seals the electrode/insulator gap providing stable heat range and superior center electrode cooling (heat flow to the insulator).

Hot-Lock Assembly

Intense pressure and heat create positive, zero-leakage, shrunken in seal between insulator and shell to contain the hot, high pressure combustion cycle gases.

Harness Wire Contact

Our smooth, uninterrupted, oxide treated spring contact surface offers enhanced corrosion resistance, is chemically bonded to the fired-in resistor providing the ultimate harness/spark plug termination integrity and energy transfer.

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Continental Motors | ||||||||||||||||||

| A-65, A-75, C-75, C-85, C-90, C115, C-125 Series | X | X | X | X | X | |||||||||||||

| C-145 Series | X | X | X | X | X | X | X | X | ||||||||||

| E165, E-185, E225 Series | X | X | X | X | X | |||||||||||||

| O-200-A, B, C, D | X | X | X | X | X | X | ||||||||||||

| IO-240-A, B | X | X | X | X | X | |||||||||||||

| O-300-A, B, C, D, E | X | X | X | X | X | X | X | X | ||||||||||

| GO-300-A, B, C, D, E, F | X | X | X | X | X | X | X | X | ||||||||||

| IO-360-A, AB, C, CB, D, DB, E, ES, G, GB, H HB, J, JB, K, KB | X | X | X | X | X | |||||||||||||

| IO-360-B | X | X | X | X | ||||||||||||||

| TSIO-360-A, AB, B, BB, C, CB, D, DB, E, EB, ES, F, FB, G, GB, H, HB, JB, K, KB, LB, MB, NB, PB, RB, SB | X | X | X | X | X | |||||||||||||

| LTSIO-360-E, EB, K, KB, RB | X | X | X | X | X | |||||||||||||

| O-470-2 | X | X | X | X | X | |||||||||||||

| O-470-4, 11, 11B, 11B-C1, 11-C1, 13, 13A, 15 | X | X | X | X | ||||||||||||||

| O-470-B, G, H, M, N, P, R, S | X | X | X | X | X | X | X | |||||||||||

| O-470-B-C1, G-C1, K-C1, L-C1, M-C1 | X | X | ||||||||||||||||

| O-470-A, E, J, K, L, | X | X | X | X | ||||||||||||||

| O-470-T, U | X | X | X | |||||||||||||||

| IO-470-A, C, G, P, R, T | X | X | X | X | X | X | X | |||||||||||

| IO-470-D, E, F, H, L, LO, M, N, S, U, V, VO | X | X | X | |||||||||||||||

| IO-470-J, K | X | X | X | X | ||||||||||||||

| L/IO-470-A | X | X | X | X | X | X | X | |||||||||||

| TSIO-470-B, C, D | X | X | X | |||||||||||||||

| IO-520 Series | X | |||||||||||||||||

| IO-520-A, B, BA, BB, C, CB, D, E, F, J, K, L, M, MB, N, NB | X | X | X | |||||||||||||||

| LIO-520 Series | X | |||||||||||||||||

| TSIO-520-A, AE, AF, B, BB, BE, C, CE, D, DB, E, EB, F, G, H, J, JB, K, KB, L, LB, M, N, NB, P, R, T, U, UB, V, VB, WB | X | X | X | |||||||||||||||

| LTSIO-520-A, AE, B, BE, C, CE, D, DB, E, EB, G, H, J, JB, K, KB, L, LB, M, N, NB, P, R, T, U, UB, VB, WB | X | X | X | |||||||||||||||

| GTSIO-520-C, D, E, F, G, H, K, L, M, N | X | X | X | |||||||||||||||

| IO-550-A, B, C, D, E, F, G, L, N, P, R | X | X | X | |||||||||||||||

| IOF-550-B, C, D, E, F, L, N, P, R | X | |||||||||||||||||

| TSIO-550-A, B, C, E, K | X | X | X | |||||||||||||||

| R9-A | X | X | X | X | ||||||||||||||

| R-670 | X | X | ||||||||||||||||

| R-670-3, -4, -8, -11, -11A | X | X | ||||||||||||||||

| W-670 | X | X | X | X | X | |||||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Continental Titan™ Engines | ||||||||||||||||||

| OX-320 series | X | X | X | X | X | X | X | |||||||||||

| IOX-320 series | X | X | X | X | X | X | X | |||||||||||

| OX-340 series | X | X | X | X | X | X | X | |||||||||||

| IOX-340 series | X | X | X | X | X | X | X | |||||||||||

| OX-360 series | X | X | X | X | X | X | X | |||||||||||

| IOX-360 series | X | X | X | X | X | X | X | |||||||||||

| OX-370 series | X | X | X | X | X | X | X | |||||||||||

| IOX-370 series | X | X | X | X | X | X | X | |||||||||||

| OX-540 series | X | X | X | X | X | X | X | |||||||||||

| IOX-540 series | X | X | X | X | X | X | X | |||||||||||

| O-340 series (ASTM certified) | X | X | X | X | X | X | X | |||||||||||

| IO-340 series (ASTM certified) | X | X | X | X | X | X | X | |||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Electroair (electronic ignition) | ||||||||||||||||||

| EIS-41000, EIS-41000IC, EIS-41000T, EIS-41000TIC, EIS-41000TLH, EIS-41000LHIC | X | X | X | x | ||||||||||||||

| Franklin/PZL/WSK | ||||||||||||||||||

| 2A-120-A, B, C, D | X | X | ||||||||||||||||

| 4A-235-B, B1, B2, B3, B4, B6 | X | X | X | |||||||||||||||

| 6AS-335-A, B | X | X | X | X | X | |||||||||||||

| 6V-335-A1A, A1B | X | X | X | X | X | |||||||||||||

| 6VS-335-A, B, A1, B1 | X | X | X | X | X | |||||||||||||

| 6A-350-C1, C1A, C2, C2A, C1L, C1R, D, D1, D1A, D1B | X | X | X | X | ||||||||||||||

| 6AS-350-A, A1 | X | X | X | |||||||||||||||

| 6V-350-A, B | X | X | X | |||||||||||||||

| PZL-3S, 3S 2nd Series, 3SR | X | X | X | X | ||||||||||||||

| ASZ-62IR-16, M18 | X | X | X | X | ||||||||||||||

| Jacobs | ||||||||||||||||||

| L-4, L-5, L-6 Series | X | X | X | X | ||||||||||||||

| 4M, 4MA, 4MA7, 4MB, 5M, 5MB, 6M, 6MA, 6MBA | X | X | X | |||||||||||||||

| R-755-A1, A2, A2M, A2M1, B1, B2, B2M, E | X | X | ||||||||||||||||

| R-755S, SM | X | X | X | |||||||||||||||

| R-755-9 | X | X | X | |||||||||||||||

| R-915-3, 5, 7 | X | X | ||||||||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Ken Royce | ||||||||||||||||||

| Ken Royce 7F, 7G | X | X | ||||||||||||||||

| Ken Royce 90 5G | X | X | ||||||||||||||||

| Kinner | ||||||||||||||||||

| B-5, B-54, C-5, K-5 | X | X | ||||||||||||||||

| Kinner R-5, R-5 Series 2, R-55, R-56 | X | X | ||||||||||||||||

| Lambert | ||||||||||||||||||

| B-5, B-54, C-5, K-5 | X | X | ||||||||||||||||

| LeBlond | ||||||||||||||||||

| LeBlond 70 5DE, 5E | X | X | ||||||||||||||||

| LeBlond 85 5F, 5DF | X | X | ||||||||||||||||

| LeBlond 90 5F | X | X | ||||||||||||||||

| LeBlond 110 7DF | X | X | ||||||||||||||||

| Menasco | ||||||||||||||||||

| Buccaneer A-6, B-6, B6S | X | X | ||||||||||||||||

| Super Buccaneer C6S-4 | X | X | ||||||||||||||||

| Pirate A-4, B-4, C4, D4, M-50 | X | X | ||||||||||||||||

| Super Pirate D-4-87 | X | X | ||||||||||||||||

| P. Ponk | ||||||||||||||||||

| O-470-50 Super Eagle | X | X | ||||||||||||||||

| Pratt & Whitney | ||||||||||||||||||

| R-985 Wasp Jr. Series | X | X | X | X | X | |||||||||||||

| R-1340 Wasp Series (Short Reach) | X | X | X | X | X | |||||||||||||

| R-1340 Wasp Series (Long Reach) | X | X | X | |||||||||||||||

| SR-1340-E | X | X | ||||||||||||||||

| R-1800 Twin Wasp E1 | X | X | X | |||||||||||||||

| R-1830 Twin Wasp Series | X | X | X | X | X | X | ||||||||||||

| R-2000 Twin Wasp Series | X | X | X | X | X | |||||||||||||

| Twin Wasp Series SC-G, SC3-G, S1C-G, S1C3-G, S3C4-G, S4C4-G | X | X | X | X | X | X | ||||||||||||

| R-2800 Double Wasp A, B, Series | X | X | X | X | X | X | ||||||||||||

| Double Wasp Series CA3, CA5, CA15, CA17, CA18, CA19, R2800-97, CB3, CB4, CB16, CB17 | X | X | X | X | X | X | ||||||||||||

| R-4630 Wasp Major Series | X | X | X | X | X | |||||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Ranger | ||||||||||||||||||

| Ranger 6-390, 6-410, 6-440 Series | X | X | X | X | ||||||||||||||

| Superior Air Parts | ||||||||||||||||||

| O-360-A1A1, A1A2, A2A1, A2A2, A3A1, A3A2, A4A1, A4A2, A5A1, A5A2, A6A1, A6A2, B1A1, B1A2, B2A1, B2A2, B3A1, B3A2, B4A1, B4A2, B5A1, B5A2, B6A1, B6A2, C1A1, C1A2, C2A1, C2A2, C3A1, C3A2, C4A1, C4A2, C5A1, C5A2, C6A1, C6A2, D1A1, D1A2, D2A1, D2A2, D3A1, D3A2, D4A1, D4A2, D5A1, D5A2, D6A1, D6A2, E1A1, E1A2, E2A1, E2A2, E3A1, E3A2, E4A1, E4A2, E5A1, E5A2, E6A1, E6A2 | X | |||||||||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Textron Lycoming | ||||||||||||||||||

| O-235-C, E, H, K, L, M, N, P Series | X | X | X | X | X | X | X | X | ||||||||||

| O-235-F, G, J Series | X | X | X | X | X | X | ||||||||||||

| O-290 Series | X | X | X | X | X | X | X | X | ||||||||||

| O-320-A, B, C, D, E, H Series | X | X | X | X | X | X | X | X | ||||||||||

| O-320-F Series | X | X | X | X | X | X | ||||||||||||

| IO-320 A, B, C, D, E, Series | X | X | X | X | X | X | X | X | ||||||||||

| IO-320-F Series | X | X | X | X | X | X | X | X | ||||||||||

| IO-320-C1A, F1A (Long Reach) | X | X | X | |||||||||||||||

| IO-320-C1B (Long Reach) | X | X | ||||||||||||||||

| AIO-320-A, B, C series | X | X | X | X | X | X | X | X | ||||||||||

| LIO-320-B Series (Short Reach) | X | X | X | X | X | X | X | X | ||||||||||

| LIO-320-C1A (Long Reach) | X | X | X | X | ||||||||||||||

| AEIO-320 A, B, C, D, E Series | X | X | X | X | X | X | X | X | ||||||||||

| O-340-A, B Series | X | X | X | X | X | X | X | |||||||||||

| O-360-A, B, C, D, F, J Series | X | X | X | X | X | X | X | X | ||||||||||

| O-360-E Series | X | X | X | X | X | X | X | |||||||||||

| HO-360-A, B, C Series | X | X | X | X | X | X | X | X | ||||||||||

| IO-360-A, B, C, D, E, F, J, K, L, M Series | X | X | X | X | X | X | X | X | ||||||||||

| IO-360-A1B6, C1A, C1F, F1A Series (Long Reach) | X | X | X | X | ||||||||||||||

| LO-360-A, C, E Series | X | X | X | X | X | X | X | X | ||||||||||

| TO-360-A, C, E, F Series | X | X | X | X | X | X | ||||||||||||

| TO-360-C1A6D, E1A6D, F1A6D Series (Long Reach) | X | X | X | X | X | |||||||||||||

| VO-360-A, B Series | X | X | X | X | X | X | X | X | ||||||||||

| AIO-360-A, B Series | X | X | X | X | X | X | ||||||||||||

| HIO-360-A, B, G Series | X | X | X | X | X | X | X | X | ||||||||||

| HIO-360 -C, D Series | X | X | X | X | X | |||||||||||||

| HIO-360-E1AD, E1BD, F1AD Series (Long Reach) | X | X | X | X | ||||||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Textron Lycoming - Continued | ||||||||||||||||||

| IVO-360-A Series | X | X | X | X | X | X | ||||||||||||

| LIO-360-C, M Series | X | X | X | X | X | X | ||||||||||||

| LTO-360-A1A6D, E1A6D | X | X | X | X | X | X | ||||||||||||

| TIO-360-A, C Series | X | X | X | X | X | X | ||||||||||||

| AEIO-360-A, B, C, H Series | X | X | X | X | X | X | X | X | ||||||||||

| AEIO-360-A Series (Long Reach) | X | X | X | X | ||||||||||||||

| LHIO-360-C Series | X | X | X | X | X | |||||||||||||

| LHIO-360-F1AD | X | X | X | X | ||||||||||||||

| IO-390-A, C | X | X | X | X | ||||||||||||||

| AEIO-390-A | X | X | X | X | ||||||||||||||

| O-435-A, C, K Series | X | X | X | X | X | X | X | |||||||||||

| O-435-B Series | X | X | ||||||||||||||||

| O-435-A1A (Long Reach) | X | X | ||||||||||||||||

| O-435-6, 6A | X | |||||||||||||||||

| O-435-23, 23A, 23B, 23C, 25, 25A | X | X | X | X | X | X | ||||||||||||

| GO-435-A Series | X | X | X | X | X | |||||||||||||

| GO-435-C, D, Series | X | X | X | X | ||||||||||||||

| GO-435-K Series | X | X | ||||||||||||||||

| VO-435-A Series | X | X | X | X | X | X | ||||||||||||

| VO-435-A, B Series (Long Reach) | X | X | X | X | X | X | ||||||||||||

| TVO-435-A Series (Short Reach) | X | X | X | X | X | |||||||||||||

| TVO-435-A, B, C, D, E, F, G Series (Long Reach) | X | X | X | X | X | X | ||||||||||||

| O-480-1, 3 | X | X | X | X | ||||||||||||||

| GO-480-B, D, F Series | X | X | X | X | X | X | X | |||||||||||

| GO-480-C, G Series | X | X | X | X | X | |||||||||||||

| GO-480-G1, G2 Series (Long Reach) | X | X | X | X | X | X | ||||||||||||

| GO-480-E1A6 | X | X | ||||||||||||||||

| GSO-480-A, B, D, F Series (Short Reach) | X | X | X | X | X | X | X | |||||||||||

| GSO-480-A, B Series (Long Reach) | X | X | X | X | ||||||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Textron Lycoming - Continued | ||||||||||||||||||

| IGO-480-A Series (Long Reach) | X | X | X | X | X | X | ||||||||||||

| IGSO-480-A Series (Short Reach) | X | X | X | X | X | X | X | |||||||||||

| IGSO-480-A Series (Long Reach) | X | X | X | X | X | X | ||||||||||||

| O-540-A, B, D, E, F, G, H, J Series | X | X | X | X | X | X | X | |||||||||||

| O-540-L3C5D, M1B5D Series (Long Reach) | X | X | X | X | ||||||||||||||

| IO-540-A, AB, AE, B, C, D, E, G, J, K, L, M, N, P, R, S, T, U, V, W, (Short Reach) | X | X | X | X | X | X | X | |||||||||||

| IO-540-AF (Short Reach) | X | X | X | X | X | |||||||||||||

| IO-540-AA, AC, AE, E, G, J, K, M, N, P, R, S, U (Long Reach) | X | X | X | X | ||||||||||||||

| IO-540-E1A5, E1B5, E1C5, J4A5, K1B5, K1B5D, K1C5, K1D5, K1E5, K1E5D, K1F5, K1F5D, K1G5, KIG5D, K1H5, K1J5, K1J5D, K1K5, K1K5D, K2A5, P1A5, R1A5 (Long Reach) | X | X | X | X | X | X | ||||||||||||

| VO-540-A, B, C Series (Short Reach) | X | X | X | X | X | |||||||||||||

| VO-540-A, B, C Series (Long Reach) | X | X | X | X | ||||||||||||||

| TIO-540-C1A, E, H | X | |||||||||||||||||

| TIO-540-A, AA, AB, AE, AF, AG, AH, AJ, AK, C, E, F, G, H, J, K, N, R, S, T, U, V, W Series | X | X | X | X | ||||||||||||||

| LTIO-540-F, J, N, R Series | X | X | X | X | X | |||||||||||||

| LTIO-540-U, V Series | X | X | X | X | ||||||||||||||

| AEIO-540-D, L Series (Short Reach) | X | X | X | X | X | X | X | |||||||||||

| AEIO-540-L Series (Long Reach) | X | X | X | X | X | |||||||||||||

| IGO-540-A, B, Series | X | X | X | X | X | |||||||||||||

| IVO-540-A Series | X | X | X | X | ||||||||||||||

| TIVO-540-A Series | X | X | X | X | X | |||||||||||||

| IGSO-540-A, B Series | X | X | X | X | ||||||||||||||

| TIO-541-A, E Series | X | X | X | X | X | X | ||||||||||||

| TIGO-541-A, E Series | X | X | X | X | X | X | ||||||||||||

| IO-580 Series (Short Reach) | X | |||||||||||||||||

| IO-580 Series (Long Reach) | X | X | X | |||||||||||||||

| AEIO-580 Series (Short Reach) | X | |||||||||||||||||

| AEIO-580 Series (Long Reach) | X | X | X | |||||||||||||||

| R-680 Series | X | X | X | X | ||||||||||||||

| IO-720-A, B, C, D Series (Short Reach) | X | X | X | X | X | |||||||||||||

| IO-720-A, B, C, D Series (Long Reach) | X | X | X | X | X | X | ||||||||||||

| MASSIVE | FINE WIRE | |||||||||||||||||

| Models | ||||||||||||||||||

| 5/8"-24 Thread | 3/4"-20 Thread | 5/8"-24 Thread | 3/4"-20 Thread | |||||||||||||||

| Warner | ||||||||||||||||||

| Scarab Series 28, 29, 30, 40, 50 | X | X | X | X | ||||||||||||||

| Scarab Jr. Series 40, 50 | X | X | X | X | ||||||||||||||

| Super Scarab Series 40, 50, 50A | X | X | X | X | ||||||||||||||

| Super Scarab 165, A, B, D, 185, 185J, 185K | X | X | X | X | ||||||||||||||

| Wright/ Curtis Wright | ||||||||||||||||||

| Cyclone Double Row Series | X | X | ||||||||||||||||

| Cyclone R-1300 Series | X | X | X | X | ||||||||||||||

| Cyclone R-1820 Series (Except F & HE) | X | X | X | X | ||||||||||||||

| Cyclone R-1820-84 (C9HE) Series | X | X | ||||||||||||||||

| Cyclone R-2600 Series | X | X | X | X | ||||||||||||||

| Cyclone R-3350-C18BA, C18BD | X | X | X | X | ||||||||||||||

| GR-540 Series | X | X | ||||||||||||||||

| GR-975 Series (Short Reach) | X | X | ||||||||||||||||

| GR-975C Series (Long Reach) | X | X | ||||||||||||||||

| R-540 Series | X | X | ||||||||||||||||

| R-975 Series (Short Reach) | X | X | ||||||||||||||||

| R-975 Series (Long Reach) | X | X | ||||||||||||||||

| Whirlwind J-5 (Short Reach) | X | X | ||||||||||||||||

| Whirlwind J-5 (Long Reach) | X | X | ||||||||||||||||

| Whirlwind R-760 Series (Long Reach) | X | X | ||||||||||||||||

| Whirlwind R-760 Series - 1/2" reach cyl. | X | X |

Information contained in this application data is for reference only. Although great effort has been made to ensure accuracy and completeness, Aero Accessories/Tempest® assumes no responsibility for the information contained within this document. Responsibility for airworthiness of aircraft, including the installation of correctly selected approved replacement of parts lies with the aircraft owner/operator per FAR 91.163, FAR 121.363, FAR 123.45, FAR 127.131 and FAR 135.143 (a). Please refer to FAA or engine/airframe/propeller manufacturers’ parts listing for approved part numbers for each application. Tempest brand products are manufactured by Aero Accessories, LLC.

| Tempest® Spark Plug Specifications | |||

| Tempest Spark Plug Part Number | Reach | Connector Threads | Electrode Design |

| UREB36S | 13/16" | 5/8" - 24 | Fine Wire |

| UREB37E | 13/16" | 5/8" - 24 | Massive |

| UREM37BY | 1/2" | 5/8" - 24 | Massive |

| UREM38E | 1/2" | 5/8" - 24 | Massive |

| UREM38S | 1/2" | 5/8" - 24 | Fine Wire |

| UREM40E | 1/2" | 5/8" - 24 | Massive |

| URHB32E | 13/16" | 3/4" - 20 | Massive |

| URHB32S | 13/16" | 3/4" - 20 | Fine Wire |

| URHB36S | 13/16" | 3/4" - 20 | Fine Wire |

| URHB37E | 13/16" | 3/4" - 20 | Massive |

| URHM38E | 1/2" | 3/4" - 20 | Massive |

| URHM38S | 1/2" | 3/4" - 20 | Fine Wire |

| URHM40E | 1/2" | 3/4" - 20 | Massive |

Q: What size spark plug does Tempest® manufacture?

A: Tempest currently manufactures only 18mm spark plugs.

Q: What spark plug should I use for my engine?

A: Please refer to the Tempest application chart. There are several things you will need to know as most engines have several different spark plugs approved.

- You will need to know your harness B-nut size. This is the nut that screws onto the spark plug. It will be either a 5/8-24” or ¾-20 thread. Be aware that a 5/8-24 utilizes a 3/4” wrench and a ¾-20 utilizes a 7/8” wrench.

- Long reach v. short reach will be determined by the specific engine.

- Heat rating is indicated by the numeric value of the spark plug part number. The lower the numeric value the colder the heat rating. Best practice is to use the same heat rated plug you have removed.

- Massive electrode or fine wire is a personal choice. Massive plugs will generally operate 400-500 hours. Fine wires can last 1500 hours. This choice is usually determined by number of annual hours flown and the size and performance of the specific engine.

Q: What Ohm value is recommended on Tempest spark plugs?

A: Typically Tempest spark plug resistors will stay between 1000 and 1500 Ohms throughout their life. Tempest specifies that the plug resistor should never be below 500 Ohms or above 5000 Ohms. We offer a lifetime guarantee on our fired-in resistor.

Q: How can I check my spark plug resistor?

A: First, the firing end of the plug must be cleaned of lead, carbon and oil. Once cleaned you can use the Tempest AT5K® or a multi-meter. If using an AT5K please see the tool section of our website. If using a multi-meter place one lead on the center electrode and the second lead on the contact point inside the spark plug terminal well. Be sure that your multi-meter is set to the correct setting.

Q: What is the best way to clean and gap my Tempest spark plugs?

A: Please visit the Technical Data portion of our website to find our articles on best cleaning practices.

Q: What causes lead fouling on my spark plug?

A: Indicated by hard ash-type deposits, lead fouling can be caused by poor fuel vaporization due to cold operating temperatures or high-lead content in the fuel (misdistribution of tetraethyl lead). Lightly fouled plugs can be cleaned, re-gapped, tested and reinstalled using a new copper mounting gasket. Severely fouled plugs should be replaced with new Tempest® spark plugs.

Q: What causes carbon fouling on my spark plug?

A: Carbon fouling is indicated by dry, fluffy, sooty deposits. The plug is operating too cold to burn off combustion deposits. This may be fuel related or ignition related. Fuel related causes include rich fuel mixture, faulty carburetor adjustment, excessive idling or improper idle mixture. Ignition causes could be related to a worn spark plug ignition lead, improper magneto timing or running too cold of a spark plug.

Q: What causes oil fouling on my spark plug?

A: Oil fouling is indicated by oily, wet deposits and frequent misfires. Causes can include damaged pistons, worn or broken piston rings, worn valve guides, sticking valves, faulty ignition supply or an engine during break-in period.

Q: Should I rotate my Tempest spark plugs?

A: Yes, you should rotate your spark plugs every 100 hours. This will help even out electrode wear caused by constant polarity and capacitance after-fire. Place them in a Tempest spark plug tray (P/N T240) and follow the rotation guide supplied on every Tempest spark plug box or in section 4.3.9 of our spark plug maintenance manual in the Technical Data portion of our website.

-

COPPER SPARK PLUG GASKET, PKG OF 100

$75.61 ea -

SPARK PLUG – FINE WIRE

$183.51 ea -

SPARK PLUG – FINE WIRE

$183.51 ea -

SPARK PLUG – MASSIVE ELECTRODE

$53.46 ea -

SPARK PLUG – MASSIVE ELECTRODE

$53.46 ea -

SPARK PLUG – MASSIVE ELECTRODE (EXTENDED REACH HEX-NUT)

$43.72 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

ANTI-SEIZE THREAD LUBE, 4OZ., MIN QTY 12

$11.38 ea -

COPPER SPARK PLUG GASKET, PKG OF 100

$87.66 ea

The most automated manufacturing processes and the most innovative spark plug in the aviation industry.

The most automated manufacturing processes and the most innovative spark plug in the aviation industry.

High Conductivity Copper Core Center Electrode

Copper, co-extruded inside a nickel alloy sleeve ensures outstanding heat and electrical conductivity while the nickel sleeve offers high resistance to corrosive combustion gases.

Proprietary Glass Center Seal

21st century ‘fired in’ resistor replaces the multipart screw, spring, and carbon pile stack up used in competitive plugs and known to suffer from resistance value instability that can cause misfires, wasted fuel, and engine roughness.

High Alumina Ceramic Insulator

High mechanical strength, superior dielectric properties, and proprietary protective glaze, provides high performance to conquer severe operational conditions. “Clean Collar™” massive electrode “V” tip focuses heat to reduce fouling and enhance heat range control.

Nickel Finish

Environmentally preferable electrolytic nickel provides outstanding durable finish, superior corrosion protection, and extreme wear resistance.

Nickel Ground Electrodes

Aviation grade nickel electrode design focuses on minimizing sparking voltage requirements while maintaining specification gaps to ensure large, stable ‘flame kernels’ for on-time ignition and complete combustion

Vacuum Infused Center Electrode

The proprietary vacuum infusion process seals the electrode/insulator gap providing stable heat range and superior center electrode cooling (heat flow to the insulator).

Hot-Lock Assembly

Intense pressure and heat create positive, zero-leakage, shrunken in seal between insulator and shell to contain the hot, high pressure combustion cycle gases.

Harness Wire Contact

Our smooth, uninterrupted, oxide treated spring contact surface offers enhanced corrosion resistance, is chemically bonded to the fired-in resistor providing the ultimate harness/spark plug termination integrity and energy transfer.

Download Spark Plug Application Sheet

Information contained in this application data is for reference only. Although great effort has been made to ensure accuracy and completeness, Aero Accessories/Tempest® assumes no responsibility for the information contained within this document. Responsibility for airworthiness of aircraft, including the installation of correctly selected approved replacement of parts lies with the aircraft owner/operator per FAR 91.163, FAR 121.363, FAR 123.45, FAR 127.131 and FAR 135.143 (a). Please refer to FAA or engine/airframe/propeller manufacturers’ parts listing for approved part numbers for each application. Tempest brand products are manufactured by Aero Accessories, LLC.

| Tempest® Spark Plug Specifications | |||

| Tempest Spark Plug Part Number | Reach | Connector Threads | Electrode Design |

| UREB36S | 13/16" | 5/8" - 24 | Fine Wire |

| UREB37E | 13/16" | 5/8" - 24 | Massive |

| UREM37BY | 1/2" | 5/8" - 24 | Massive |

| UREM38E | 1/2" | 5/8" - 24 | Massive |

| UREM38S | 1/2" | 5/8" - 24 | Fine Wire |

| UREM40E | 1/2" | 5/8" - 24 | Massive |

| URHB32E | 13/16" | 3/4" - 20 | Massive |

| URHB32S | 13/16" | 3/4" - 20 | Fine Wire |

| URHB36S | 13/16" | 3/4" - 20 | Fine Wire |

| URHB37E | 13/16" | 3/4" - 20 | Massive |

| URHM38E | 1/2" | 3/4" - 20 | Massive |

| URHM38S | 1/2" | 3/4" - 20 | Fine Wire |

| URHM40E | 1/2" | 3/4" - 20 | Massive |

Q: What size spark plug does Tempest® manufacture?

A: Tempest currently manufactures only 18mm spark plugs.

Q: What spark plug should I use for my engine?

A: Please refer to the Tempest application chart. There are several things you will need to know as most engines have several different spark plugs approved.

- You will need to know your harness B-nut size. This is the nut that screws onto the spark plug. It will be either a 5/8-24” or ¾-20 thread. Be aware that a 5/8-24 utilizes a 3/4” wrench and a ¾-20 utilizes a 7/8” wrench.

- Long reach v. short reach will be determined by the specific engine.

- Heat rating is indicated by the numeric value of the spark plug part number. The lower the numeric value the colder the heat rating. Best practice is to use the same heat rated plug you have removed.

- Massive electrode or fine wire is a personal choice. Massive plugs will generally operate 400-500 hours. Fine wires can last 1500 hours. This choice is usually determined by number of annual hours flown and the size and performance of the specific engine.

Q: What Ohm value is recommended on Tempest spark plugs?

A: Typically Tempest spark plug resistors will stay between 1000 and 1500 Ohms throughout their life. Tempest specifies that the plug resistor should never be below 500 Ohms or above 5000 Ohms. We offer a lifetime guarantee on our fired-in resistor.

Q: How can I check my spark plug resistor?

A: First, the firing end of the plug must be cleaned of lead, carbon and oil. Once cleaned you can use the Tempest AT5K® or a multi-meter. If using an AT5K please see the tool section of our website. If using a multi-meter place one lead on the center electrode and the second lead on the contact point inside the spark plug terminal well. Be sure that your multi-meter is set to the correct setting.

Q: What is the best way to clean and gap my Tempest spark plugs?

A: Please visit the Technical Data portion of our website to find our articles on best cleaning practices.

Q: What causes lead fouling on my spark plug?

A: Indicated by hard ash-type deposits, lead fouling can be caused by poor fuel vaporization due to cold operating temperatures or high-lead content in the fuel (misdistribution of tetraethyl lead). Lightly fouled plugs can be cleaned, re-gapped, tested and reinstalled using a new copper mounting gasket. Severely fouled plugs should be replaced with new Tempest® spark plugs.

Q: What causes carbon fouling on my spark plug?

A: Carbon fouling is indicated by dry, fluffy, sooty deposits. The plug is operating too cold to burn off combustion deposits. This may be fuel related or ignition related. Fuel related causes include rich fuel mixture, faulty carburetor adjustment, excessive idling or improper idle mixture. Ignition causes could be related to a worn spark plug ignition lead, improper magneto timing or running too cold of a spark plug.

Q: What causes oil fouling on my spark plug?

A: Oil fouling is indicated by oily, wet deposits and frequent misfires. Causes can include damaged pistons, worn or broken piston rings, worn valve guides, sticking valves, faulty ignition supply or an engine during break-in period.

Q: Should I rotate my Tempest spark plugs?

A: Yes, you should rotate your spark plugs every 100 hours. This will help even out electrode wear caused by constant polarity and capacitance after-fire. Place them in a Tempest spark plug tray (P/N T240) and follow the rotation guide supplied on every Tempest spark plug box or in section 4.3.9 of our spark plug maintenance manual in the Technical Data portion of our website.

-

COPPER SPARK PLUG GASKET, PKG OF 100

$75.61 ea -

SPARK PLUG – FINE WIRE

$183.51 ea -

SPARK PLUG – FINE WIRE

$183.51 ea -

SPARK PLUG – MASSIVE ELECTRODE

$53.46 ea -

SPARK PLUG – MASSIVE ELECTRODE

$53.46 ea -

SPARK PLUG – MASSIVE ELECTRODE (EXTENDED REACH HEX-NUT)

$43.72 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – FINE WIRE

$172.33 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

SPARK PLUG – MASSIVE ELECTRODE

$41.98 ea -

ANTI-SEIZE THREAD LUBE, 4OZ., MIN QTY 12

$11.38 ea -

COPPER SPARK PLUG GASKET, PKG OF 100

$87.66 ea